In this article, we’ll go over seven different ways to join PVC pipes and fittings for a structural project.

There are many ways to connect PVC piping, but it’s crucial to figure out which one is best for you. You can physically bond the PVC pipe together or make a temporary connection depending on the technique you use.

Depending on your project and what you have available, different connection methods are appropriate. In this article, we’ll examine the fundamentals of creating a strong connection, the ways in which fittings improve connections, and various techniques for connecting PVC pipes.

Table of Contents

Useful Tools to Connect PVC Piping

Make sure you have some basic piping tools on hand before beginning to connect PVC piping. This includes:

- A pipe cutter (or a suitable saw for cutting pipe)

- Sandpaper or a utility knife (for dealing with post-cut burrs)

- A marker (to mark joints)

- Rags (for cleaning drips or spills)

- Extra pipe

- Your connecting method of choice

Make sure you have a fundamental understanding of the connections you need to make and the caliber of the work they must support.

Tips and Safety for Connecting PVC Piping

In the event that you make a mistake when cutting your pipe or connecting your fittings, it is a good idea to have extra pipe and fittings on hand. This is especially crucial when using methods that are more durable, like solvents.

Even with push-on or threaded connections, clean your PVC before connecting it. For removing dirt, dust, and grime, a PVC cleaner is effective. Burrs that lead to clogs and obstruct tight connections can be removed from the pipe using 80-grit sandpaper.

Protect your skin and the area where you are working if you are using solvents. Wear safety gear, such as a ventilator, safety goggles, and gloves, and ventilate the area as much as you can.

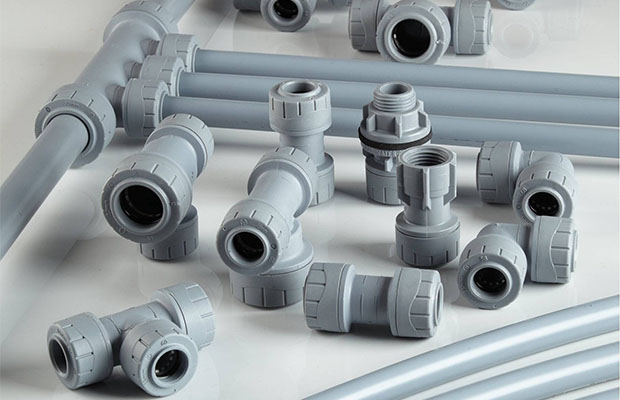

PVC Fittings Basics

To join pipes together, PVC fittings are utilized. There are several types that allow you to do things, such as:

- Attach two pipes to create one longer pipe

- Change the direction of your PVC

- Make quick connections

PVC fittings are available in standard sizes that cinch around your PVC; however, for a successful connection, the diameter must be selected. Despite the fact that PVC fittings can keep your pipe in place, a pipe joint by itself is not water-safe.

Furniture Grade Vs. Regular PVC Fittings

Fittings are available in furniture grade and standard varieties, similar to PVC pipe.

PVC that is intended for furniture is more resistant to sun damage and degradation, so it is less likely to change when exposed to UV light. Additionally, the fittings’ exterior is unmarked and more impact-resistant.

Furniture-grade fittings should be used when connecting PVC that will be visible to the public or be used outdoors.

Types of PVC Fittings

Fittings come in a wide range of styles, allowing you to connect your PVC in various ways and create a variety of angles.

Some of the most common include:

- Adapters: also known as reducing couplings; change the end type of PVC pipe so it fits different sizes and types of PVC

- Bushings: usually threaded; mainly used to connect PVC pipes with different connectors via reduction

- Caps and Plugs: stop the flow in a pipe (caps at the end of pipe and plugs inside other fittings); plugs usually have as a spigot or a male threaded end

- Couplings: connect two pipes together in a straight line; some reduce to connect small and large pipes

- Crosses: form a “plus”; useful when creating framework

- Elbows: come in different angles; allow you to direct pipe around objects; side elbows have three ends to create corners

- Flanges: allow you to connect PVC to non-PVC products (i.e. the base of a toilet); resemble a disc and create a seal between the object and the PVC

- Nipples: fitting with two male-threaded ends used to connect two female-threaded ends

- Unions: not as permanent as couplings; feature a ring for easy deconstruction; often used in temporary builds

- Tees: shaped like a “T” with a two ends in a straight line and a third at the side; allow you to split a line into two with a perpendicular connection (or connect two into one)

Most PVC connections utilize a fitting in some way. The way you connect your PVC pipe depends on your fitting and the project’s intended use.

Methods to Connect PVC Piping

The most common and effective methods to connect PVC piping include:

- Dry fitting

- Fasteners

- Silicone or glue

- PVC solvents

- Flex couplings

- Push on fittings

- Threaded PVC connections

Standard fittings are sufficient for the first 4 methods, but special fitting designs are required for the final 3 techniques. It’s crucial to pick the best method for your project because some don’t produce a watertight seal.

1. Dry Fitting

The most straightforward method of joining PVC pipe is dry fitting, but you shouldn’t rely on it as a long-term fix. Simply insert your PVC pipe into the fitting to accomplish this.

A dry fit will eventually back out, especially when put under pressure, even though PVC pipe fits snugly in fittings of the right size.

Before using more durable connection techniques, it is advised that you dry fit your PVC and label your connections. Often, this is your last chance to fix things easily and quickly.

2. Fasteners

Without using PVC cement, you can quickly and securely fasten PVC pipe and fittings together using fasteners (screws) to provide a strong structural hold. As a result, you can reuse or move the fittings at a later time. The only drawbacks to this method of joining PVC are that it isn’t as strong as PVC cement and that it won’t work for internal-fit components like couplings and dome caps. Here is how to connect PVC together with fasteners:

- Put the pipe inside the fitting. Use a mallet if necessary to pound it into place completely. Verify that it is fully seated.

- Use a 1/8″ drill bill to make a pilot hole about midway where the pipe and fitting meet, into the side of the fitting. The screw insertion will be simpler as a result.

- Put a self-tapping, threaded screw into the pilot hole you just drilled using a power drill or driver. Verify the screw’s length to ensure that it can pass through the pipe and fitting.

3. Silicone and Glue

Regular adhesives, like silicone and glue, perform admirably with low-impact projects, but they still have a chance to lose their hold over time. Connections that carry vapor or water cannot be held in place with silicone or glue.

Use a PVC cleaner on the inside of your fitting and the outside of your pipe before you use silicone or glue to connect PVC pipe. To strengthen the connection, you might also want to use sandpaper to make the connecting surfaces rough.

Before inserting the PVC pipe into the fitting, apply glue to one surface. Hold it in place for as long as necessary to allow the adhesive to set for the advised amount of time, preferably more.

Even when combined with the fastener method, silicone or glue is still likely to separate over time. Consider using a specialized solvent to connect your PVC for more robust connections and less hassle.

4. PVC Solvents/ PVC Cement

In order to permanently join the pieces together, most connections call for the use of a PVC solvent (such as PVC glue or PVC cement) that melts the surface of the pipe and the fitting. You require this if you intend to connect PVC for plumbing.

Prior to applying a PVC solvent, make sure you remove any burrs. If burrs are to blame for the connection failing, you cannot simply try again because they can clog drain lines and interfere with the connection on the outside.

Before applying your solvent, give your surface a final coat of PVC primer. Your pvc will be cleaned, its surface will be made softer, and the primer will act as a visual indicator of its use (for inspection purposes).

Apply the solvent before inserting your PVC pipe into the fitting. To prevent it from backing out, turn the pipe just a little and then hold it there for at least 15 seconds.

Before doing any more handling, give the solvent at least 20 minutes to cure.

5. Flex Couplings

You can connect PVC pipe without permanently welding the pieces together by using flexible couplings, like those made by Fernco. Flexible couplings provide reliable seals and durable holds, but they are not approved for all applications.

Strong steel band clamps are used in flexible couplings to hold the rubber tightly around your PVC pipe.

Your PVC pipe must be inserted into the flex coupling and firmly seated therein to complete the connection. To create a seal and stop the pipe from backing out, tighten the clamp.

6. Push-On Fittings for PVC

Push-on fittings are a unique kind of connector that do not require welding or adhesive. Instead, they have an inner ring with spurs that strengthen the connection.

A connection of this kind is one that lasts forever. A saw is required to separate the parts after inserting PVC inside the fitting.

For quick repairs in some systems, push-on fittings are a fantastic option. They can be utilized in the majority of covert applications and have an o-ring to create a watertight seal.

The best method for connecting PVC for your project usually depends on your comfort level.

7. Threaded PVC Pipes

Another choice for those who don’t want to deal with solvents or permanent connections is threaded PVC pipes and fittings.

Lower pressure ratings and a higher failure rate are associated with threaded connections. For reliable connections, threaded PVC must be properly joined.

Apply a PVC thread sealant made especially for this purpose after using a strong PVC cleaner to clean your PVC pipe and fitting. Apply the pipe to your fighting and turn it until there is no more give.

When tightening the connection, you can use a wrench, but be careful not to overdo it. This could result in leaks by causing cracks.

The Dos and Don’ts of Gluing PVC Pipe

Speed and accuracy count when gluing PVC pipe, so avoid mishaps with this guide to creating an

The procedure involves cleaning and preparing the PVC by priming both the outside of the pipe and the inside of the fitting. Following a quick 10 second dry time, you apply cement to the same areas, insert the pipe tightly into the fitting, and wait for the cement to dry.

Although it may seem straightforward, it’s easy to screw up when gluing PVC pipe, and if you do, you’ll have to cut the pipe out and start over. So take note of this list of advice for success in your PVC projects.

DON’T Use the Wrong Type of Cement.

For various types of plastic piping, there are various cements (and primers) available on the market. Make sure to choose cement designed specifically for PVC by carefully reading labels. Be aware that one type of pipe cement you may see on the shelf is designed for CPVC (chlorinated polyvinyl chloride) pipe, which is similar in name but not an acceptable substitute. Weld-On, Oatey, Gorilla, and more are well-known producers of PVC cement. You can find their products on Amazon.

DO a Dry Fit.

Lay out all the PVC pipe pieces before you glue them together to ensure that they will fit together smoothly and are cut to the precise length you require. So that you don’t glue the incorrect connections together, mark and number the connections as necessary.

DON’T Neglect Safety Warnings.

Because PVC primer and cement are messy to handle, the manufacturers advise avoiding contact with the eyes and skin. Put on the protective gloves and safety goggles (ideally with side shields) before you begin. To make difficult cleanup less of a hassle in the event of drips, you might want to spread a towel or tarp over your work surface. As a chemical solvent that can release toxic fumes, PVC pipe cement should only be used in well-ventilated areas.

DON’T Leave Jagged Edges.

Make sure to remove any burrs from the edges of the cut surface with coarse sandpaper or a utility knife after cutting the PVC pipe with a specialized tool called a PVC pipe cutter (view example on Amazon). Burrs, if left attached, can either clog pipes by catching debris that is already flowing through them or reduce the seal’s efficacy.

DO Work Fast.

Only a few seconds remain after applying the primer before applying the cement. The pipe will then be put into the fitting right away. When gluing PVC pipe, work quickly; if the cement starts to dry before you’re ready, reapply it.

DO Twist for a Secure Fit.

When inserting the pipe into the fitting, rotate it by 25%. A tighter fit will result from the glue’s ability to spread in this way. The pipe may pop back out if you don’t hold the fitting and pipe tightly together for at least 30 seconds.

DO Allow Enough Cure Time.

Give the pipe at least 20 minutes before handling it again so the cement has time to properly set after 30 seconds of holding it in place. You can use the glue for your project after it has cured for the specified amount of time, usually 24 hours, as stated in the product’s instructions.

Conclusion: Connect PVC Piping

Use a connection method that works for your project and experience, and make sure it works. When possible, concentrate on methods that will help you build connections that will last.

Remember to:

- Dry fit your pipe before making permanent decisions

- Clear burrs and clean your PVC

- Follow instructions specific to the materials you use

Any queries you may have about connecting PVC piping should be left in a comment below!

FAQs

Can I Use Gorilla Glue Instead of PVC Glue?

To put it plainly, Gorilla Glue has nothing to grip or bind to because the surface of PVC is so smooth. So it may work in a pinch but will come apart later down the road when you need it to work the best. You might have to wait hours for this type of glue to cure because it has a very long setup time.

What Happens If You Glue PVC Without Primer?

The strength and durability of the joint connection are maximized by PVC primer. A joint will still weld together without the primer, but the connection will not be as strong as the primer allows the cement itself to penetrate deeper into the material.