It can be challenging to remove stripped, old, and worn-out hex screws from metal or wood. Following instructions to remove a stripped hex screw can be difficult if you don’t have the right tools.

The internal slots or drives on hex screws’ heads set them apart from other kinds of mechanical fasteners. A mechanical wrench must be used in place of a screwdriver to tighten or loosen a hexhead screw.

There are, however, some guidelines for removing stripped hex screws from metal and wooden bars. You can quickly remove these screws using the methods we’ve listed below.

Table of Contents

What is a Hex Head Screw?

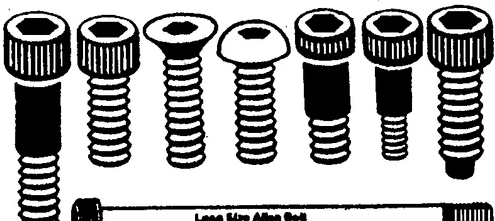

Mechanical fasteners called hex screws are used in the assembly of metal and wood components. These screws, also known as hex-head and hex-cap, have flat heads that are hexagonal in shape as opposed to being circular at the top.

These screws’ threads can be completely threaded or only partially threaded. Fully threaded screws cover the entire shank, whereas partially threaded screws have an unthreaded portion.

Hex screws range in diameter from 0.25 to 3 inches, as specified by ANSI/ASME B18.2.1-1996. The height ranges between 0.15 and 1.935 inches, and the thread is 0.75 – 6.5 inches long.

Hex screws, such as the Allen screw and hex bolt, are frequently mistaken for other fasteners because of their similar appearances. But in various ways, each of these is distinct from hex screws.

For instance, a hex screw has a hexagonal-shaped head without a drive or slot. But an Allen screw has a hexagonal space for an Allen wrench and a cylindrical head.

A hex bolt, on the other hand, is a completely distinct mechanical fastener. To tighten and guard the bolt against stripping, a nut and washer are attached to its body.

Hex caps’ quality varies according to the material used to make the screw. These are categorized based on the type of steel used and how tough the screws are under pulling pressure.

Listed below are classifications of hex-cap screws under the SAE classification:

- Screws made of low- to medium-carbon steel are perfect for use in homes and are classified as Grade 2 and below. No markings at all indicate these.

- Grade 5 — Three line markings designate this category, which includes medium-quality carbon steel screws for automotive work.

- Grade 8 screws are the best choice for demanding tasks like the fabrication of metal for tractors and suspension systems. Five lines are marked on the screw heads.

- Medium carbon steel that has been quenched and tempered is used to make these bolts, grade 8.8. Grade 8.8 bolts have good tensile strength and function well in most environments. They are used in railroad equipment, motors, engines, and processing equipment.

- These metric bolts, grade 10.9, are made of low-carbon boron steel that has undergone quenching and tempering along with medium carbon steel and medium carbon steel alloy. Metric 10.9 bolts are strong enough to hold large, forged parts together and are also used in automotive applications. They also have good wear resistance.

The American Society for Testing and Materials (ASTM) in addition to SAE has developed a classification system for screws. In some industries, a grading scheme other than the ISO is also in use.

Why Do Hex Screws Get Stripped?

Hex screws can become stripped over time, just like other screws. It involves tearing the hexagonal screw head, which makes it challenging to separate from wooden or metal bars.

Why do these hex screws deteriorate over time? It might result from the use of inappropriate and subpar tools.

Some people might neglect to confirm that the screw’s size corresponds to the screwdriver or drill bit size. It’s possible that some people are using outdated or worn-out drills and drivers to tighten the screw.

The stripping of the hex screws can also be caused by improper handling and working on screws. More specifically, you might have overtightened a screw or used an old, worn-out screw.

In the end, you’ll struggle to remove the screw from the metal or wooden surface.

5 Ways to Remove a Stripped Fastener Head

Finally, before your boss learns, we get to the information you really wanted to know. Here are five methods for removing a stripped screw head. Depending on the circumstance, the order in which they are presented is the order I advise. Each improved method runs the risk of harming the screw and the surrounding material. The amount of stripping increases as you move down the list.

1. Use a Rubber Band.

This trick works well when the fastener is small or only slightly stripped, such as on electronics or decorative furniture fasteners. Prior to using a driver, make sure it is the right size and type for the fastener. Next, cover the fastener’s head with a rubber band. The fastener should then be slowly backed out while being pressed down firmly with the driver. To give you a more positive engagement as you drive the screw, the rubber band helps to close any gaps. Duct tape or thin cardboard will do the trick if you don’t have access to rubber bands.

2. Use Pliers.

Use a pair of locking pliers (Vice Grips) to firmly grasp the screw head if the fastener’s head is fully exposed and there is little chance that it will break off. The screw should be grasped by the pliers so firmly that the head slightly dents. Gently spin the fastener’s head with the pliers until it is free enough to be removed with your fingers.

3. Make It a Different Drive Style.

This method necessitates a little more force being applied to the screw head. Decide on a driver style and size that is roughly similar to the original but a little larger. If the driver style was a Philips, choose a slightly larger Philips, for instance. Tap with a hammer after inserting the slightly larger driver into the fastener’s head. To increase screw engagement, you try to make a small indentation with the driver in the screw head. Just enough pressure should be applied to the fastener head to slightly dent it and seat the driver. After that, press firmly and pull away slowly.

Using a slightly larger dissimilar driver style may help if the thread is severely stripped in this technique. Some examples include using a flat head inside of a Philips or a slightly oversized Torx driver inside of a hex. The sharp edges of the flathead and Torx drivers will dent the fastener and “bite” in more tightly. USE CAUTION: This method might harm your driver. Use at your own risk.

4. Make It Flat Head.

If the screw head is visible and undamaged, this simple trick practically always works. Create a small groove in the faster head using a Dremel, saw, or file. Once the groove is deep enough, remove the screw with a common flathead fastener. Just keep in mind to remove slowly while going slow with the driver. The head of the fastener will be permanently damaged by this method. You run the risk of breaking the fastener’s head if the groove is cut off-center or if the head is too thin. Additionally, you run the risk of harming the work surface.

5. Use a Screw Extractor.

A commercially available tool for removing stripped screws is a screw extractor. Figure 6 displays two different types of extractors. The old screwdriver head must first be removed through drilling. One option for doing this is to use a combination extractor’s built-in drill or a standard twist drill. The screw extractor is then inserted into the freshly drilled hole. The spiraling twists in the extractor rotate in the opposite direction. The spirals of the extractor function as the threads of the screw you are attempting to unscrew. The spirals on the extractor want to grab the hole walls when it is inserted into the freshly drilled hole and spun counterclockwise. The stripped screw wants to spin in the opposite direction from the extractor and back out as a result of this grabbing effect.

Because screw extractors will permanently damage what is left of the fastener’s drive head, I usually save using them for my final effort. They also fundamentally weaken the fastener, rendering all other techniques ineffective. In other words, once you choose a screw extractor, it better work because otherwise, your options are constrained.

5 Tips to Prevent Hex Screws Stripping

Building and putting together wood and metal furniture requires the use of hex screws and machine screws. These tiny objects, though, can be harmed by misuse because they are so delicate.

Here are some preventative steps you can take to stop stripping hex screws.

Use the Proper Screwdriver Size

Screws are available in a variety of styles, dimensions, and shapes. Even hex screws cannot all be used with the same screwdriver.

The size and shape of the screws you’re using should be checked as a result. A screwdriver shouldn’t be pushed into a screw that isn’t compatible.

Use Durable Screw Products

The strong material and tensile strength used to make screws differ from one another. Frequently, those made of inferior steel may not be able to withstand the pressure from demanding applications.

Because of this, it’s crucial to use sturdy screw products. You can use these screw specifications to determine which mechanical fasteners are best for your project.

Don’t Use Excessive Force

Since we already discussed tensile strength, applying too much force when handling these hex screws can also compromise their quality. Take care when using the screws you have for construction and repair.

Read More: Car Battery Is Hot (6 Reasons + Solutions)

Make Sure Your Screws Are Correctly Aligned With the Axis

In order to improve their hold on the surface where they stick, screws are made to rotate in a single direction. A hex screw’s grooves and head could be damaged if you try to turn it the other way.

Be Careful on Using Power Tools

Power tools apply pressure and force to the screws, in contrast to manual screw insertion. The screws could end up being stripped, though, with improper use.

Take care when using these power tools, and go slowly when working. Determine the speed and force required for the screw because not all screws can withstand increased pressure.

Summary

Hex screw stripping is a common issue brought on by using the wrong tools for these fasteners. The removal of a stripped hex screw can be accomplished in a number of ways, though.

Hex screws are susceptible to excessive force, just like all other screws and mechanical fasteners. This is why it’s important to understand how to properly handle the screws you use.

Last but not least, increasing productivity and efficiency is knowing the proper screws and tools to use for the job. The best wood and metal products for your company can be made with the assistance of these.

FAQs

Are Allen and Hex the Same Screw?

Despite the fact that Allen and Hex screws have hexagonal-shaped screw heads, people frequently confuse them, this is not the case.

Hex-cap screws in this situation have hexagonal flat heads without a slot for keys or screwdrivers. Allen screws, on the other hand, have hexagonal drives and circular tops designed for Allen wrenches.

What Are Hex Screws Used For?

Hex screws can be used in more demanding situations where hard fasteners and high tensile strength are needed. Depending on the classified grade, these may be appropriate for building bridges, assembling wood and metal blocks, and fabricating metal.

Is Torx Better Than Hex?

Hex screws can be upgraded to torque screws, which need star-shaped keys. Additionally, these wrenches rotate Torx screws with more force than hex keys do with hex screws.

However, some contend that hex keys and wrenches are more widely available than Torx. If we discuss their accessibility, it makes hex screws and keys more advantageous.

How Do You Screw a Hex Bolt?

Different from hex-cap screws are hex bolts. The latter lacks a washer and nut, which are components found on hex bolts.

Almost identical to how screws are inserted into holes, these bolts. On the other end of the thread, however, is where the washer and nut are inserted to complete the fastening process.