The exhaust gas recirculation valve, or EGR valve for short, is a crucial component of the car’s engine management system and recirculates precisely measured amounts of exhaust gas to the engine intake system for improved engine efficiency, lower fuel consumption, and lower NOx emissions.

Exhaust gas recirculation (EGR) is a technique for reducing Nitrogen Oxide (NOx) emissions, which are created as a byproduct during the combustion process. There are two default settings for the EGR valve: open and closed, although the position can vary anywhere in between.

The EGR valve will become more crucial going forward due to mounting pressure to reduce emissions. What it does, why it fails, and how to replace it when it does are all critical knowledge to have. Let’s start.

Table of Contents

What Is An EGR Valve?

Exhaust Gas Recirculation (EGR) is an approach used in contemporary internal combustion engines to regulate Nitrogen Oxide (NOx) emissions, which are created as a byproduct during the combustion process.

In the combustion chamber, the fuel ignites in the presence of ambient air, which is primarily an oxygen and nitrogen mixture. As temperatures rise, NOx emissions are produced.

In order to reduce combustion temperatures and the amount of NOx released into the atmosphere, the EGR system returns a small amount of exhaust gas to the engine’s combustion chambers through the intake manifold.

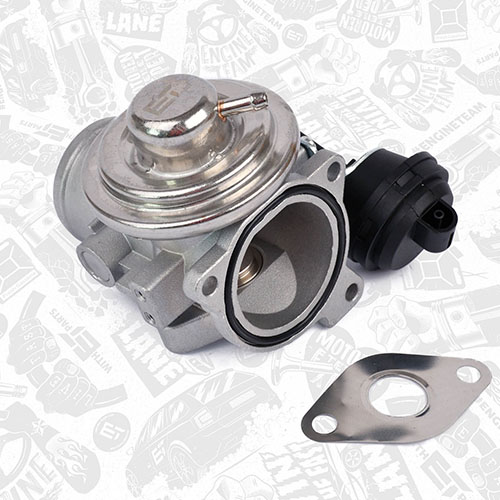

The main element of the EGR system is the EGR valve, which is typically closed. It joins the intake and exhaust manifolds and is operated by a vacuum or an electric step motor that is already there. Depending on the engine load, the EGR valve’s job is to regulate the flow of exhaust gas that is recirculated.

Related Reading: What Is A PCV Valve?

How Does An EGR Valve Function?

In order to reduce NOx emissions and thereby comply with strict emissions regulations, the majority of modern vehicles have EGR valves built into their design. EGR systems return a portion of the combustion chamber’s exhaust gas for re-combustion with brand-new intake air.

This decreases the amount of oxygen in the combustion mixture and raises the water vapor content, lowering the peak combustion temperature. The EGR valve significantly lowers the amount of NOx that the engine produces because more NOx is produced as peak combustion temperature rises.

The EGR valve starts to function once the engine has started, reached the proper operating temperature, and the speed of the vehicle increases. The EGR valve gradually modifies the exhaust gas flow.

The EGR valve will return to its closed position once the car slows down and the engine shuts off, stopping the flow of exhaust gases.

Different Types Of EGR Valve

Although there are many different types of EGR valves—older systems use a vacuum-operated valve, while more recent vehicles use an electronic control system—the main types can generally be categorized as follows:

Diesel high-pressure EGR valves divert the high-flow, high-soot exhaust gas before it enters the diesel particulate filter – the soot can combine with the oil vapor to create sludge. The gas is then returned to the inlet manifold via a pipe or internal cylinder head drill. Since a vacuum in the inlet manifold is not present naturally in diesel engines, a secondary valve is additionally used to help create one.

Diesel Low-pressure EGR valves divert the exhaust gas after it has passed through the diesel particulate filter — this gas has a lower flow but is almost completely clean of soot. Once again, a pipe transports the gas to the inlet manifold.

Gasoline EGR valves divert the exhaust gases, much like the high-pressure diesel equivalent. The exhaust gases are drawn into the vacuum produced by cylinder depression, and the flow is controlled by the EGR valve’s own opening and closing.

Vacuum-operated EGR valves use a vacuum solenoid to vary the vacuum to the diaphragm and, in turn, open and close the Some valves also come with a feedback sensor to let the ECU know where the valve is in relation to the EGR.

Digital EGR valves feature a solenoid or stepper motor and, in most cases, a feedback sensor. To control the flow of exhaust gas, these valves receive a pulse width modulated signal from the ECU.

Potential Problems With An EGR Valve

The EGR valve frequently sticks due to a buildup of carbon deposits. The worst-case scenario is a complete blockage of the EGR valve and EGR passages, which would stop the process of recirculating the exhaust gases.

In addition to increased fuel consumption or decreased performance, clogged EGRs frequently result in black smoke escaping the exhaust. If the EGR valve fails to open or close, the engine warning light will illuminate on the dashboard.

A failing EGR valve can also be identified by a strong fuel odor coming from inside the car, as the increased fuel consumption will cause more hydrocarbons to be released through the exhaust. Due to the smell’s obnoxious characteristics, which may be harmful to human health, it is easily detected.

What Indicates A Bad EGR Valve?

What takes place when the valve malfunctions? The following is important information regarding your car’s EGR valve:

EGR Valves Take A Lickin’

Due to regular wear and tear from constant use, EGR valves eventually fail. Over time, the components deteriorate due to wear-and-tear and carbon particle buildup, which could clog the parts.

The Telltale Knock

You might notice decreased fuel economy in your car and hear the engine knocking if the EGR valve fails. According to Delphi, owners might notice decreased engine performance in the form of sluggish acceleration and a rough idle.

The Check Engine Light Is On. Check Engine

A faulty EGR valve will probably also turn on the check engine light in the car, as it does with most engine component problems. Obviously, a variety of problems can cause the check engine light to come on, so the next step in determining the problem is to have your car’s computer checked for error codes.

Things To Consider About A Failing EGR Valve

Since many other engine management components exhibit symptoms that are similar to those of an EGR valve failure, EGR faults continue to be a source of frustration for many technicians. However, there are a few warning signs to watch out for:

- Check engine light: as with most engine management components, a problem with the EGR valve might make the check engine light come on.

- Engine performance problems: if the valve is stuck open the vehicle’s air-fuel ratio will be disrupted causing engine performance issues such as reduced power, poor acceleration, and rough idle. It might also result in leaks in the turbo boost pressure, which would make the turbo work harder.

- increased NOx emissions when the EGR valve is left closed, the combustion chamber will reach high temperatures and a lot of fuel will remain unburned, increasing NOx emissions and decreasing fuel efficiency.

- Engine knock: the higher temperatures and Additionally, NOx may lead to more detonation or knock, which can be audible as engine knocking.

How To Troubleshoot An EGR Valve?

Given the variety of EGR valve types, it is always recommended to adhere to the troubleshooting steps outlined in the service manual; nonetheless, there are a few universal steps that can aid in accurate diagnosis:

- Using a diagnostic tool, check for any fault codes on the EGR valves that are electronically controlled.

- Verify the connections and positioning of all electrical and vacuum lines.

- The vacuum supply hose should be checked for vacuum between 2000 and 2500 rpm using a vacuum gauge. At normal operating temperatures, the absence of a vacuum would indicate a loose hose, a blocked or malfunctioning ported vacuum switch or solenoid, or a broken vacuum amplifier/pump.

- While the engine is running, check the vacuum solenoid. Use a scan tool to turn on the solenoid on electronically controlled EGR valves, then check the vacuum at the pipe’s end. EGR operation will be impacted if the solenoid does not open when energized, is stuck in the open or closed position, has a corroded electrical connection, a loose wire, or poor ground. Before replacing, determine the underlying cause.

- If possible, check the valve stem’s movement between 1500 and 2000 rpm. If the valve is operating properly, the stem should move; if not, and there is a vacuum, there is a problem.

- Depending on the kind of EGR valve, directly apply vacuum to it using a hand vacuum pump or scan tool. If there is no improvement in the idle quality, either the EGR valve is broken or the passages are totally blocked. A faulty control system is the root of the issue if the engine stalls or idles poorly.

- Take the EGR valve off, then inspect it for carbon buildup. Remove any carbon if at all possible, being careful not to contaminate the diaphragm.

- Examine the manifold’s EGR passageway for obstructions and clean it as necessary.

Tips To Replace A Faulty EGR Valve

- Remove the engine cover first.

- In order to remove the electrical connections and/or vacuum lines and inspect them for damage, first loosen the electrical cable on the valve.

- Check the valve for damage, corrosion, or carbon build-up after removing the fastening screws.

- After thoroughly cleaning the EGR valve mounting surface, install the new valve and gasket. The EGR supply port should also be cleared of any loose carbon.

- Reattach the EGR valve to the housing by aligning the gasket and bolt holes.

- To the recommended torque settings, tighten all fasteners.

- Reattach the vacuum hoses and/or electrical connections once you’ve got everything securely in place.

- Reset the engine management light lastly and look for any additional errors using a diagnostic scan tool. Perform a road test after making sure the malfunction indicator lamp has been turned off. The EGR valve must now frequently be reset in order to accommodate modifications. By doing this, the ECU can easily learn the stop position at the open and closed points. If you don’t do this, the valve might break and fall into the manifold.

EGR Valve & An Mot Test

In the past, car owners attempted to remove EGR valves and Diesel Particulate Filters (DPFs) from their vehicles to avoid costly repairs.

The Department of Transportation has now stated that it is illegal to remove the EGR valve or DPF from vehicles that are compliant with the Euro 6 Emissions Standards because doing so renders the vehicle ineligible for use on public roads.

Vehicles will also fail their MOT test due to emission levels emitted and owners can face an astounding £1,000 fine for removing either an EGR valve or a diesel particulate filter.