What is PEX pipe? In both new construction and remodeling projects, flexible plastic called cross-linked polyethylene (PEX) is currently taking the place of conventional copper and galvanized steel water supply lines.

The biggest advancement since the flush toilet is PEX piping. Most homeowners can now easily perform plumbing work on their own thanks to the development of PEX pipes and simple-to-use pipe connectors.

Discover more about PEX in the following paragraphs, including its definition, applications, and advantages and disadvantages. PEX is a widely used plumbing material.

Other Posts You Might Like: How To Bend PVC Pipe?

Table of Contents

What Is PEX Piping?

Cross-linked polyethylene, also known as PEX piping, is less expensive than copper piping and installs much more quickly. PEX also simplifies remodeling projects because it is flexible. PEX has a strong “memory;” it always wants to spring back to its original shape. Consequently, manipulating a coil of PEX is like battling a huge Slinky. You’re better off buying 10-ft for the majority of jobs. “sticks” instead. You might have to install a coupler or two and pay a few cents more per foot, but you’ll avoid frustration and kinks. Even plumbers who install miles of PEX every year prefer to purchase sticks over coils.

PEX Revolution

German scientist Thomas Engle discovered in 1968 how to use radiation to crosslink polyethylene, a common plastic, to create a much more flexible version of the substance. The flexible PEX pipe, also known as PEX tubing, was created from the new plastic when it first arrived in the US in the 1980s. Originally, radiant floor heating systems used the flexible tubing embedded in a concrete slab to heat the slab and radiate heat throughout the rest of the room. Radiant floor heating still makes use of PEX pipe.

PEX has been widely used for water supply systems in Europe since the 1980s, but it was introduced later in the US due to some early versions’ slight degradation when exposed to the high chlorine levels typical of US water supplies. Since PEX complied with our requirements for potable drinking water over the past 20 years and was made suitable for carrying drinking water by adding antioxidants during manufacturing, it has gained popularity.

Early PEX water systems were the subject of complaints when the fittings connecting the pipes failed and leaked. That issue was resolved by better fittings, which led to a rise in PEX’s popularity. More than 60% of residential water supply systems installed in new homes today use PEX.

Is Pex Reliable?

In other countries, PEX has been used for decades; there are thousands of homes with 30-year-old, leak-free PEX. Instead of the tubing itself, the majority of PEX system issues, both in the US and abroad, were caused by improper installation or faulty fittings.

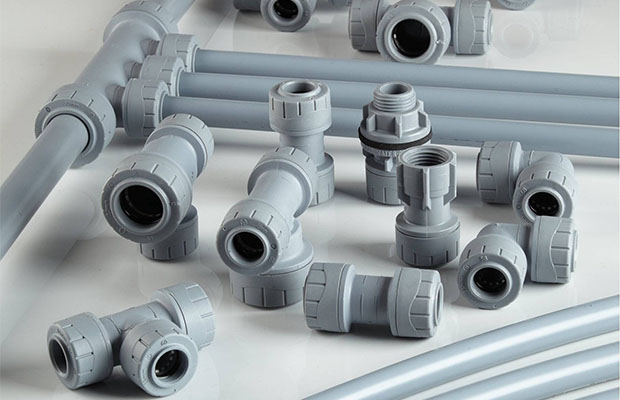

How To Join Pex Pipes?

Thermal Expansion

Joining PEX pipes is possible using the thermal-expansion technique. The process of thermal expansion entails heating the PEX pipe’s end with a heat gun to cause it to expand.

It takes little time to attach the expanded end to the fitting. The pipe will shrink as it cools and cinch tightly around the fitting.

Push Fit

Using a connector with a push-fit design is another way to join PEX pipes. It won’t be necessary to use any tools with this kind of connector.

Simply insert the connector’s one end into the plumbing fitting by hand, and then insert the PEX pipe into the connector’s other end.

In the pipe and fitting, the connector will fit securely. One of the most popular ways for DIY plumbing enthusiasts to connect PEX pipes is with this connector.

Clamp Rings

Similar to copper rings, clamp rings operate. They typically surround a pipe. With the aid of a unique plumbing tool, they are pressed firmly into place.

Crimp

PEX pipes are simply inserted into a brass fitting to be crimped together. Around the plumbing connection, copper rings will be placed.

To slightly deform the rings and make sure they fit snugly in place, you’ll need to use a special crimping tool.

PEX Pipe Advantages

There are many benefits of PEX piping, including:

- install at a lower cost. The price of PEX is roughly one-third that of copper piping. The cost savings can really add up if whole-home piping is something you want in new construction. Furthermore, PEX is less susceptible to price changes than other markets, where copper is more expensive.

- Corrosion resistance. In contrast to copper and galvanized steel pipes, PEX is resistant to corrosion, mineral buildup, and erosion.

- Ease of installation. Although there are specialized tools needed, many small DIY projects don’t necessitate a plumbing license. A leaky sink, for instance, can have old pipes replaced. PEX can be easily installed in confined spaces because of its flexibility.

- Efficiency. Due to the shorter wait time for hot water caused by PEX pipes’ smaller diameter compared to other types of pipes, less water is wasted. In addition, PEX material has better thermal conductivity characteristics than other types of pipes, which lowers heat loss.

- Quiet operation. Due to the fact that PEX pipes are made of synthetic plastic, you won’t have to worry about them rattling.

PEX Pipe Disadvantages

- Installation errors. While some people might find installing PEX to be simple, others might find it challenging. In particular, if there are more moving parts, lines need to be run from other rooms, or the installation is taking place in brand-new construction, we advise leaving pipe installation to the experts.

- Heat damage. Although there are connection materials to work around this issue, PEX cannot be installed directly to water heaters due to its susceptibility to failure in high-heat conditions. Furthermore, recessed lighting cannot be placed close to it.

- UV light. All PEX piping needs to be protected from UV light because PEX is extremely sensitive to it. For PEX pipes, many manufacturers advise complete darkness, which restricts where it can be installed.

- Chemical issues. It has been documented that some types of PEX can leach harmful substances like BPA. High chlorine levels in the water can also harm PEX. Before installing PEX, always test your water to ensure that it is safe to use.

- Permeability. Rodents can even chew through PEX pipes because they are plastic, making damage more likely. Installation outside or exposure to the elements are not recommended for PEX. Because PEX is permeable, liquids may enter the pipe.

Prior to installing PEX pipes in your home, always conduct research and speak with a plumber.

Label Lingo

The manufacturing procedure used to create the tubing allows us to differentiate between the various types of PEX. Rolls with an A, B, or C designation may be found when shopping for PEX. Choose the tubing best suited to your needs:

- Utilizing peroxide, PEX-A is produced. The most adaptable of the three types of PEX, this type is appropriate for all plumbing needs related to the supply of water to homes. Because it expands the most when exposed to freezing water, it is the material that is least likely to crack in extremely cold temperatures. Although it is more expensive than B or C, it is simple to work with. Depending on the brand and diameter, a 10-foot length of PEX-A costs $3.50 to $7.50. PEX-A is not significantly superior to PEX-B aside from flexibility.

- Using a moisture-cure process, PEX-B is created. PEX-B is slightly stiffer than PEX-A, and has a distinct coil “memory” that makes the tubing want to return to its original coiled state. However, the coil memory is not a barrier to installation, and PEX-B is frequently the tubing of choice for residential plumbing because it also expands to resist cracking when water freezes but is less expensive than PEX-A: A 10-foot section of PEX-B costs $2.50 to $5.50, depending on brand and diameter. In addition, PEX-B has improved chlorine resistance, making it a good option in areas with heavily chlorinated water.

- Irradiation is used in the production of PEX-C. The stiffest version, PEX-C, is the most challenging to work with because it is more likely to kink and crack when water freezes. It is also the most difficult to work with because of its stiffness. Due to these undesirable characteristics, PEX-C works best for quick repairs that don’t require bending around tight corners. The least expensive option is PEX-C, which can range in price from $1.75 to $3.50 for a 10-foot section, depending on the brand and diameter.

Different Sizes Of Pex Tubing And Pipes

Common Diameters Of Pex Pipes

Three-quarter inch diameter: Specially made for use in supplying water from a water heater, a ¾ inch pipe. Providing cold water to the house is another use for it.

The first 18 inches (in length) of a PEX pipe cannot, however, be used as the water line from a water heater according to the majority of plumbing codes.

Half-inch diameter: Branch supply lines are typically constructed using ½ inch pipe. It is the most typical size that most do-it-yourself plumbers run into.

Water for fixtures like the shower, bathtub, kitchen sink, and bathroom sink comes from branch lines that branch off of the main supply line.

Common Lengths Of Pex Pipes

The fact that PEX pipes come in incredibly long sections sets them apart from copper and galvanized pipes in a significant way.

PEX tubing coils come in lengths between 100 and 500 feet. Such long pipes are ideal for multi-branched plumbing systems that run numerous supply lines and branches from a central location.

Also available are shorter lengths, ranging from 4 to 10 feet. For DIY enthusiasts, shorter PEX lengths are ideal.

How To Make PEX Connections?

You’ll need the appropriate equipment and materials to connect PEX pipe in a watertight manner. The fittings and connectors used for each of the aforementioned connecting techniques must be an exact match to the PEX pipe’s size. There are hundreds of different fitting types—typically made of brass—that can be used to connect PEX to existing copper or steel pipes and to connect it to fixtures. Additionally, fittings for fusing pipes of various sizes are readily available. To make the connections secure, use one of the next five techniques.

- Copper crimping: Using copper crimping rings (view on Amazon) is one of the most popular ways to connect PEX, but doing so necessitates the use of a unique PEX crimping tool (view on Amazon). A fitting is then inserted into the PEX tube after the copper ring has been slid over the end of the tube. Finally, using a PEX crimping tool, the copper ring (and tube) are tightly secured in place after being pushed to the tube’s end and over the fitting.

- Expansion connections: In order to connect PEX using the expansion method, the diameter of the PEX tube must first be stretched using a specialized PEX expander tool (view on Amazon). In order to form a watertight seal around the fitting, the PEX tube then contracts back to its original size.

- Stainless steel clamps (SSC): The SSC method of connecting PEX entails tightening stainless steel rings around PEX connections with a ratchet clamping tool (view on Amazon). Before inserting the fitting, the steel ring is slid over the PEX tube, much like the copper crimping technique. The ring is then tightened firmly around the tube and the fitting by applying pressure to a tab on it with the ratchet clamping tool.

- Compression fittings: A tapered plastic compression ring is placed over the PEX tube’s end before a threaded brass nut (view on SupplyHouse) is slid over it. In the end of the PEX tube, a hollow brass tube is then inserted. The entire assembly is then screwed onto the end of a threaded fitting after being inserted into the fitting’s threaded end. As the nut is tightened, a seal is made by pressing the plastic compression ring up against the end of the brass fitting.

- Push-fit connections: The quickest way to connect PEX is with the push-fit method, which involves purchasing special push-fit fittings that “grab” the end of the After being inserted over the end, PEX pipe (view on Amazon). Push-fit fittings don’t need any special tools to be used, but after they’ve been connected, you’ll need a special removal ring to take them off the pipe’s end. As a child, if you ever played with one of those paper tube “traps” that grabbed your finger when inserted into the tube, you get the idea of how push-fit connecting works.

Usage Tips For PEX Pipes

- Use only the recommended PEX connection tools for the best outcomes. For instance, using pliers to crimp a connecting ring won’t produce the same tight fit as using a PEX crimping tool.

- Since PEX pipes deteriorate in UV light, keep them indoors and away from sunny windows.

- Make tidy end cuts with a PEX cutter for simpler handling.

Do I Need Special Equipment?

Yes, you can connect PEX pipes using stab-in or compression fittings, but these materials are too expensive to be used on large projects. Most PEX supply jobs require connections, which calls for a unique tool. Only two PEX supply connection techniques are practical for DIYers and are sufficiently affordable, crimp rings and cinch clamps.

When using a crimp ring tool, you slip a band of metal, typically copper, over the fitting. The main disadvantage is the requirement for separate crimping tools for one-half inch and three-quarter inch fittings, or for a universal tool with interchangeable inserts (not shown).

Cinch clamps function more similarly to the conventional band clamps you are probably familiar with. The protruding tab is covered by the cinch clamp tool, and you squeeze to tighten the cinch clamp. All cinch clamp sizes can be tightened with the same tool, but we prefer the one-handed model in the picture because it allows you to hold the ring in place with one hand while tightening it with the other.

The only other unique tool required is a cutter for the tubing that resembles a pair of scissors.

Pex Vs. Copper: Which One Is Better?

PEX has several advantages over copper pipes:

- PEX is cheaper than copper. About one-third of the cost of copper is spent on half-inch PEX tubing. In order to install the fittings, a specialized tool will be purchased with some of the savings. However, PEX typically costs less than copper if you’re doing a medium- to a large-scale plumbing project.

- PEX fittings are faster to install than copper. A manifold and “home-run” system makes connecting a garden hose to each fixture incredibly quick and simple. The connections can still be made more quickly than with copper soldering even if PEX fittings are installed in a traditional main line and branch system.

- Copper won’t corrode in a PEX supply. Copper can corrode over time if you reside in an area with acidic water. The better option in these locations is a PEX supply because it is unaffected by acidic water.